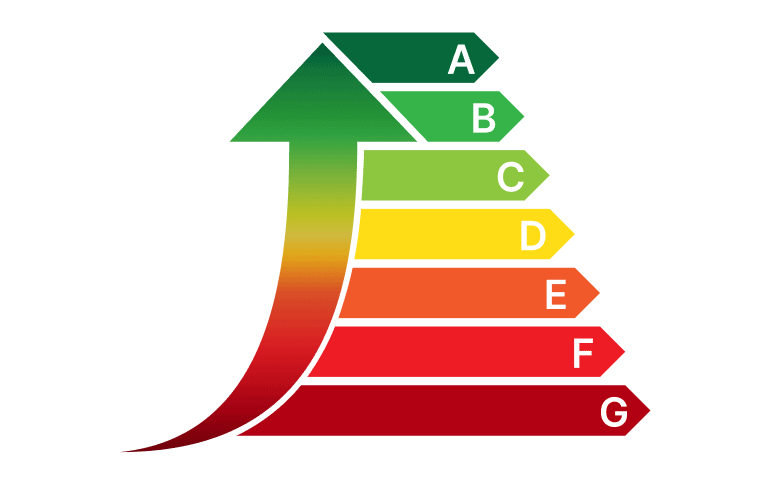

Smart insulation with durability and environmental sensitivity

The BSP Structural Block consists externally of 2.5 cm of integrated fiber-reinforced two-sided cement mortar, while its interior contains two layers of blue self-extinguishing EPS 80 insulation. Between the two insulating layers, reinforced gravel concrete is placed.

The materials used in the BSP Structural Block are ecological and environmentally friendly. They do not contain chlorofluorocarbons (CFCs), hydrochlorofluorocarbons (HCFCs), or hydrofluorocarbons (HFCs). They do not promote the growth of fungi or bacteria, nor do they attract insects or rodents. The block is 100% recyclable, provided it is disposed of at an appropriate final recipient.

100%

Recyclable materials, environmentally friendly